Nema 23 (57 mm) hibridni koračni motor, bipolarni, 4-pinski, ACME vodeći vijak, niska razina buke, dugi vijek trajanja, visoke performanse.

Nema 23 (57 mm) hibridni koračni motor, bipolarni, 4-pinski, ACME vodeći vijak, niska razina buke, dugi vijek trajanja, visoke performanse.

Ovaj hibridni koračni motor od 57 mm dostupan je u tri vrste: s vanjskim pogonom, kroz os i kroz fiksnu os. Možete birati prema svojim specifičnim potrebama.

Ovaj motor dostupan je u veličinama 20 mm, 28 mm, 35 mm, 42 mm, 57 mm, 86 mm

Duljina koraka, 0,001524 mm ~ 0,127 mm

Performanse Maksimalni potisak do 240 kg, nizak porast temperature, niske vibracije, niska buka, dugi vijek trajanja (do 5 milijuna ciklusa), visoka točnost pozicioniranja (do ±0,01 mm)

Opisi

| Naziv proizvoda | 57 mm hibridni koračni motori |

| Model | VSM57HSM |

| Tip | hibridni koračni motori |

| Kut koraka | 1,8° |

| Napon (V) | 2,3 / 3 / 3,1 / 3,8 |

| Struja (A) | 3/4 |

| Otpor (Omi) | 0,75 / 1 / 0,78 / 0,95 |

| Induktivnost (mH) | 2,5 / 4,5 / 3,3 / 4,5 |

| Olovne žice | 4 |

| Duljina motora (mm) | 45 / 55 / 65 / 75 |

| Temperatura okoline | -20℃ ~ +50℃ |

| Porast temperature | Maks. 80 tisuća |

| Dielektrična čvrstoća | 1 mA maks. @ 500 V, 1 kHz, 1 s |

| Otpor izolacije | 100MΩ min. pri 500Vdc |

Certifikati

Električni parametri:

| Veličina motora | Napon /Faza (V) | Trenutni /Faza (A) | Otpornost /Faza (Ω) | Induktivnost /Faza (mH) | Broj Olovne žice | Inercija rotora (g.cm2) | Težina motora (g) | Duljina motora L (mm) |

| 57 | 2.3 | 3 | 0,75 | 2,5 | 4 | 150 | 580 | 45 |

| 57 | 3 | 3 | 1 | 4,5 | 4 | 300 | 710 | 55 |

| 57 | 3.1 | 4 | 0,78 | 3.3 | 4 | 400 | 880 | 65 |

| 57 | 3.8 | 4 | 0,95 | 4,5 | 4 | 480 | 950 | 75 |

Specifikacije i parametri performansi vodećeg vijka

| Promjer (mm) | Dovesti (mm) | Korak (mm) | Sila samozaključavanja pri isključivanju (S) |

| 9.525 | 1,27 | 0,00635 | 800 |

| 9.525 | 2,54 | 0,0127 | 300 |

| 9.525 | 5.08 | 0,0254 | 90 |

| 9.525 | 10.16 | 0,0508 | 30 |

| 9.525 | 25,4 | 0,127 | 6 |

Napomena: Za više specifikacija vodećeg vijka, molimo kontaktirajte nas.

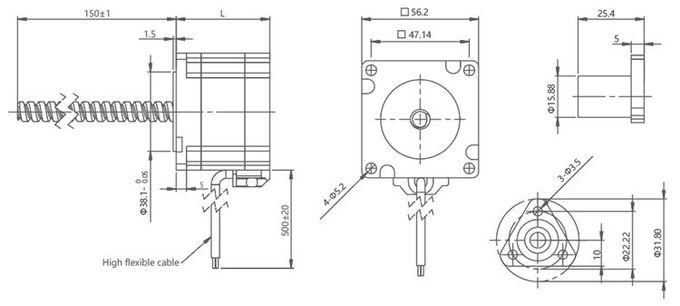

Standardni nacrt vanjskog motora VSM57HSM:

Bilješke:

Duljina vodećeg vijka može se prilagoditi

Prilagođena obrada je izvediva na kraju vodećeg vijka

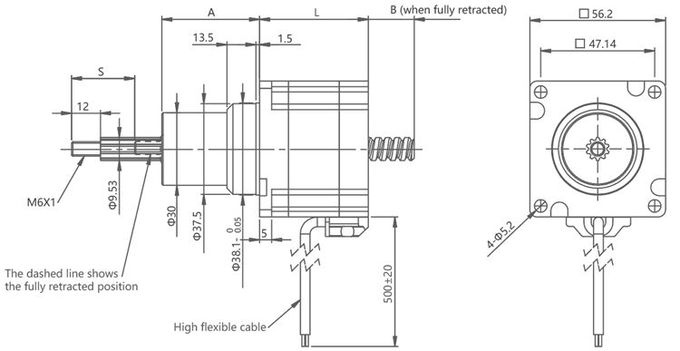

Crtež obrisa standardnog zatvorenog motora za hibridne koračne motore od 57 mm:

Bilješke:

Prilagođena obrada je izvediva na kraju vodećeg vijka

| Moždani udar S (mm) | Dimenzija A (mm) | Dimenzija B (mm) | |||

| L = 45 | L = 55 | L = 65 | L = 75 | ||

| 12,7 | 24.1 | 1.1 | 0 | 0 | 0 |

| 19.1 | 30,5 | 7,5 | 0 | 0 | 0 |

| 25,4 | 36,8 | 13,8 | 4,8 | 0 | 0 |

| 31,8 | 43.2 | 20.2 | 11.2 | 0,2 | 0 |

| 38.1 | 49,5 | 26,5 | 17,5 | 6,5 | 0 |

| 50,8 | 62,2 | 39,2 | 30.2 | 19.2 | 9.1 |

| 63,5 | 74,9 | 51,9 | 42,9 | 31,9 | 21,9 |

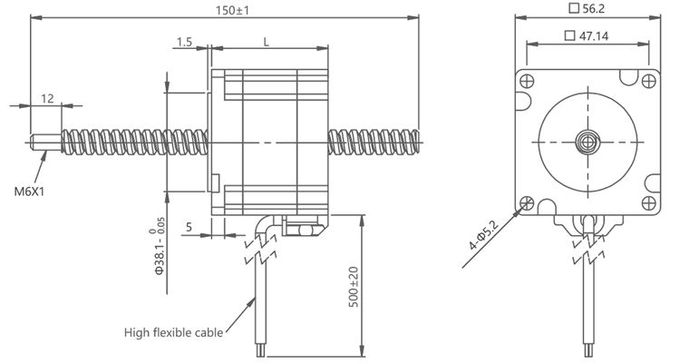

Crtež obrisa standardnog fiksnog motora s hibridnim koračnim motorom od 57 mm

Bilješke:

Duljina vodećeg vijka može se prilagoditi

Prilagođena obrada je izvediva na kraju vodećeg vijka

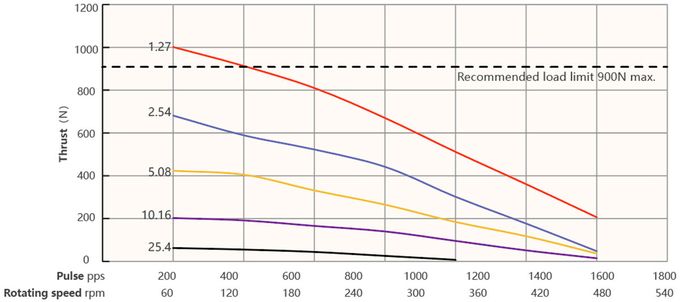

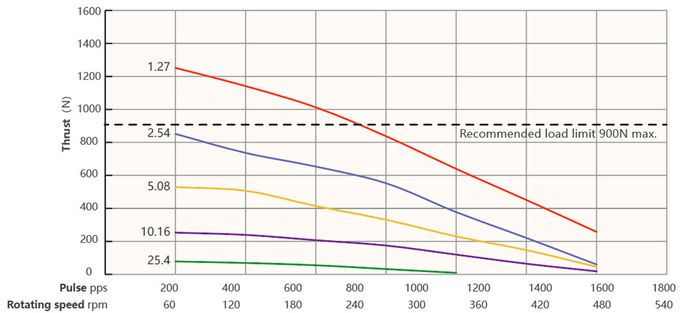

Krivulja brzine i potiska:

Bipolarni Chopper pogon serije 57, duljine motora 45 mm

100% strujna frekvencija impulsa i krivulja potiska (vodeći vijak Φ9,525 mm)

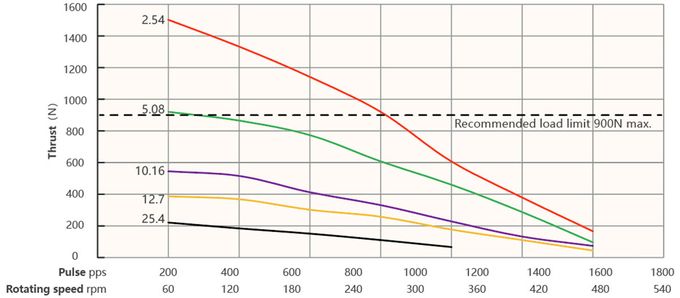

Bipolarni Chopper pogon serije 57, duljine motora 55 mm

100% strujna frekvencija impulsa i krivulja potiska (vodeći vijak Φ9,525 mm)

| Razmak (mm) | Linearna brzina (mm/s) | ||||||||

| 1,27 | 1,27 | 2,54 | 3,81 | 5.08 | 6.35 | 7,62 | 8,89 | 10.16 | 11.43 |

| 2,54 | 2,54 | 5.08 | 7,62 | 10.16 | 12,7 | 15.24 | 17,78 | 20.32 | 22,86 |

| 5.08 | 5.08 | 10.16 | 15.24 | 20.32 | 25,4 | 30,48 | 35,56 | 40,64 | 45,72 |

| 10.16 | 10.16 | 20.32 | 30,48 | 40,64 | 50,8 | 60,96 | 71,12 | 81,28 | 91,44 |

| 25,4 | 25,4 | 50,8 | 76,2 | 101,6 | 127 | 152,4 | 711.8 | 203.2 | 228,6 |

Uvjet testiranja:

Pogon sjeckalice, bez ubrzavanja, polu-mikro-korak, napon pogona 40V

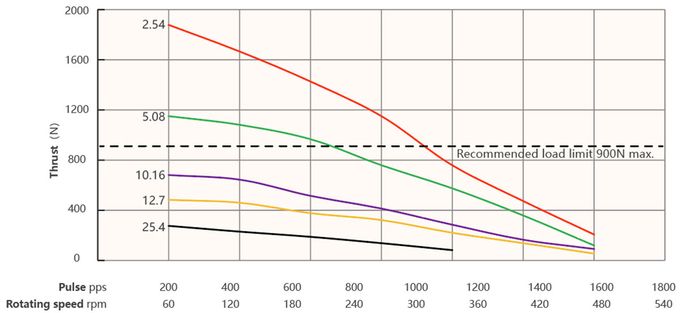

Bipolarni Chopper pogon serije 57, duljine motora 65 mm

100% strujna frekvencija impulsa i krivulja potiska (vodeći vijak Φ9,525 mm)

Bipolarni Chopper pogon serije 57, duljine motora 75 mm

100% strujna frekvencija impulsa i krivulja potiska (vodeći vijak Φ9,525 mm)

| Razmak (mm) | Linearna brzina (mm/s) | ||||||||

| 1,27 | 1,27 | 2,54 | 3,81 | 5.08 | 6.35 | 7,62 | 8,89 | 10.16 | 11.43 |

| 2,54 | 2,54 | 5.08 | 7,62 | 10.16 | 12,7 | 15.24 | 17,78 | 20.32 | 22,86 |

| 5.08 | 5.08 | 10.16 | 15.24 | 20.32 | 25,4 | 30,48 | 35,56 | 40,64 | 45,72 |

| 10.16 | 10.16 | 20.32 | 30,48 | 40,64 | 50,8 | 60,96 | 71,12 | 81,28 | 91,44 |

| 25,4 | 25,4 | 50,8 | 76,2 | 101,6 | 127 | 152,4 | 711.8 | 203.2 | 228,6 |

Uvjet testiranja:

Pogon sjeckalice, bez ubrzavanja, polu-mikro-korak, napon pogona 40V

Područja primjene

3D ispis:Hibridni koračni motori od 57 mm široko se koriste u 3D pisačima za kontrolu položaja i kretanja glave pisača.

CNC alatni strojevi:U CNC (računalno numerički upravljanim) strojevima, 57-milimetarski hibridni koračni motori koriste se za upravljanje kretanjem alata za rezanje radi preciznih operacija obrade.

Oprema za automatizaciju:Hibridni koračni motori od 57 mm mogu se koristiti u raznim automatizacijskim uređajima, kao što su automatski strojevi za pakiranje, automatski sustavi za sortiranje, automatske montažne linije itd., za kontrolu kretanja i pozicioniranja.

Tekstilni strojevi:U tekstilnoj industriji, hibridni koračni motori od 57 mm mogu se koristiti za upravljanje predilnicama, tkalačkim stanovima i drugom opremom kako bi se osigurala točnost i stabilnost tekstilnog procesa.

Medicinska oprema:Hibridni koračni motori od 57 mm široko se koriste u medicinskoj opremi kao što su medicinske pumpe za šprice, medicinski roboti, oprema za skeniranje slika itd. za preciznu kontrolu položaja i kontrolu kretanja.

Robotika:Hibridni koračni motori od 57 mm koriste se u raznim robotskim primjenama, uključujući industrijske robote, servisne robote, kolaborativne robote itd., za precizno kretanje i manipulaciju.

Automatizirani skladišni sustavi:U automatiziranim skladišnim i logističkim sustavima, hibridni koračni motori od 57 mm mogu se koristiti za upravljanje transportnim trakama, dizalima, dizalicama i drugom opremom kako bi se postiglo točno pozicioniranje i rukovanje predmetima.

Ovo su samo neke od tipičnih primjena hibridnih koračnih motora od 57 mm, a zapravo se široko koriste u mnogim drugim područjima, uključujući opremu za ispis, sigurnosne sustave, precizne instrumente i tako dalje.

Prednost

Visok omjer okretnog momenta i veličine:Unatoč svojoj kompaktnoj veličini, hibridni koračni motori od 57 mm mogu isporučiti visoki okretni moment. To ih čini prikladnima za primjene gdje je prostor ograničen, ali je potreban visoki okretni moment.

Upravljanje u otvorenoj petlji:Hibridni koračni motori mogu raditi u sustavu upravljanja s otvorenom petljom, što znači da im nisu potrebni uređaji za povratnu informaciju o položaju poput enkodera. To pojednostavljuje sustav upravljanja i smanjuje ukupne troškove.

Precizno pozicioniranje:Hibridni koračni motori pružaju precizne mogućnosti pozicioniranja zahvaljujući svojoj inherentnoj rezoluciji koraka. Mogu se pomicati u malim koracima, što omogućuje točno pozicioniranje i ponovljivost.

Glatki rad:Hibridni koračni motori mogu postići glatki rad, posebno kada se pokreću tehnikama mikrokoraka. Mikrokoraci dijele svaki korak na manje podkorake, što rezultira glatkijim kretanjem i smanjenim vibracijama.

Brzo vrijeme odziva:Hibridni koračni motori imaju brzo vrijeme odziva, što omogućuje brzo ubrzanje i usporavanje. Ova značajka je korisna za primjene koje zahtijevaju dinamične i agilne pokrete.

Visoka pouzdanost i izdržljivost:Hibridni koračni motori poznati su po svojoj robusnosti i pouzdanosti. Imaju dugi radni vijek, niske zahtjeve za održavanjem i mogu izdržati teške radne uvjete.

Isplativo rješenje:U usporedbi s drugim tehnologijama upravljanja gibanjem poput servo motora, hibridni koračni motori općenito nude isplativije rješenje. Pružaju dobru ravnotežu između performansi i pristupačne cijene.

Jednostavna integracija:Hibridni koračni motori široko su dostupni i kompatibilni s raznim pogonskim elektronikom i upravljačkim sustavima. Mogu se lako integrirati u različite vrste strojeva i automatizacijskih postavki.

Energetska učinkovitost:Hibridni koračni motori troše energiju samo kada su u pokretu, što ih čini energetski učinkovitima. Kada su mirujući, ne zahtijevaju kontinuirano napajanje, što doprinosi ukupnoj uštedi energije.

Zahtjevi za odabir motora:

►Smjer kretanja/montaže

►Zahtjevi za opterećenje

►Zahtjevi za moždani udar

►Zahtjevi za završnu obradu

►Zahtjevi za preciznost

►Zahtjevi za povratnu informaciju enkodera

►Zahtjevi za ručno podešavanje

►Zahtjevi zaštite okoliša

Proizvodna radionica

.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)